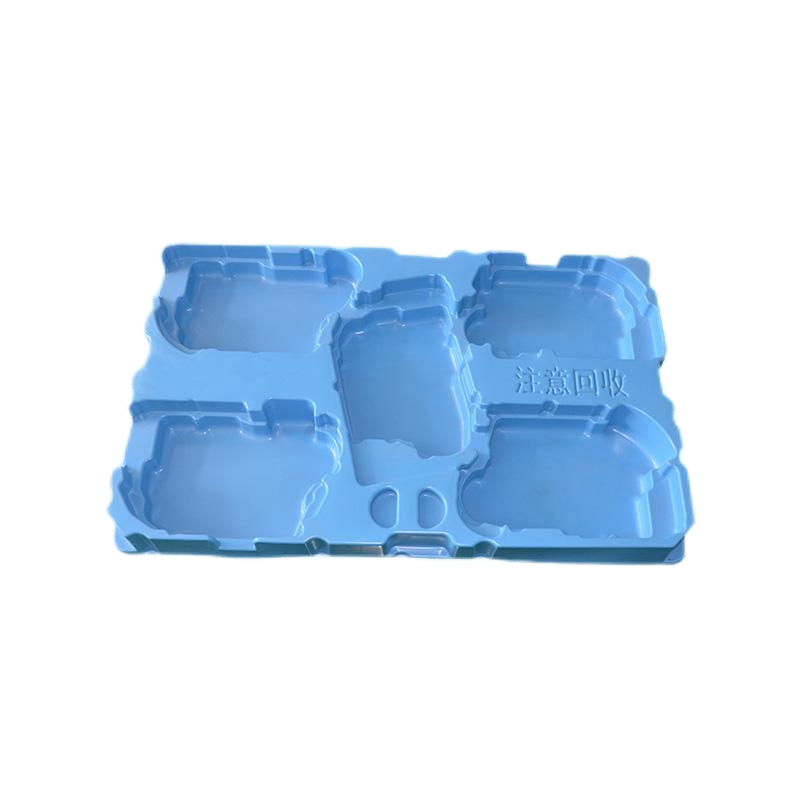

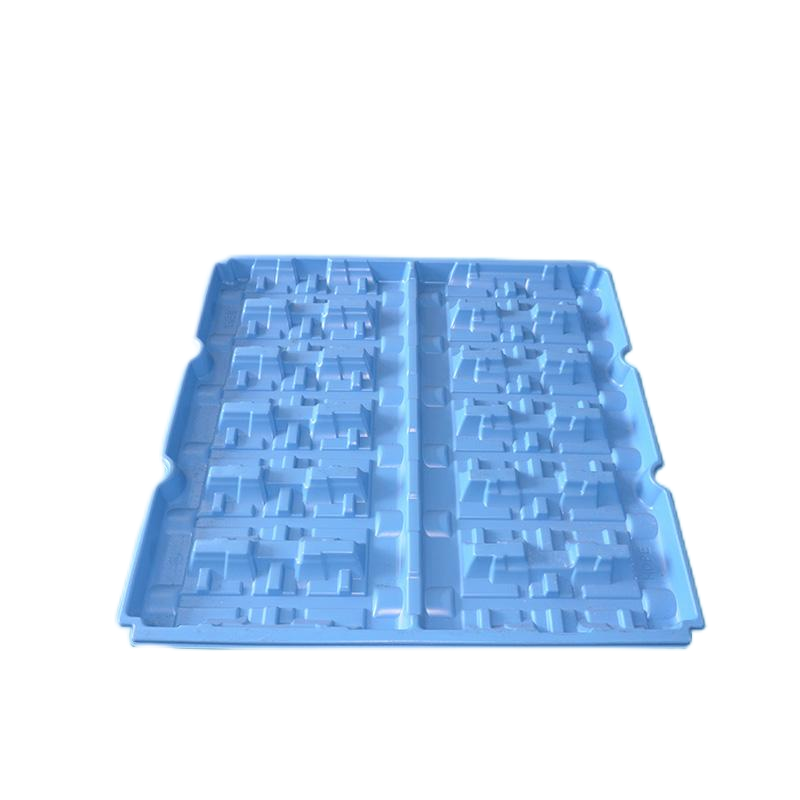

Custom: Prototype Design

Process Type: Thermoforming

Industrial Use: Automotive, Bottom tray

Application: Logistics, Factory, Supply Chain

Customized HDPE thermoforming trays have become increasingly popular in the automotive industry for their ability to protect and organize various parts effectively. These trays, constructed from durable high-density polyethylene (HDPE) material, offer exceptional strength and resistance to impact and chemicals.

The key advantage of customization lies in the ability to tailor these trays precisely to fit the specific dimensions and requirements of automotive parts. Advanced thermoforming techniques empower manufacturers to create trays with intricate designs, including slots, compartments, and dividers, ensuring secure placement and easy organization of components.

Moreover, HDPE thermoforming trays can be equipped with anti-static properties, making them ideal for safeguarding sensitive electronic elements against electrostatic discharge (ESD). By significantly reducing the risk of ESD-related malfunctions or failures, these trays enhance the reliability and performance of automotive systems.

The lightweight nature of HDPE thermoforming trays offers additional benefits in terms of efficiency and cost-effectiveness. Their reduced weight simplifies handling and minimizes physical strain on workers, ultimately enhancing productivity. Furthermore, the lighter weight also leads to lower shipping costs, resulting in overall savings throughout the supply chain.

Additionally, these trays embrace environmental considerations by being recyclable, aligning with sustainable practices in the automotive industry. At the end of their lifespan, the trays can be processed through recycling programs, contributing to waste reduction and conservation of resources.

In summary, customized HDPE thermoforming trays provide exceptional protection and organization for automotive parts. Their customization options, anti-static properties, lightweight design, and recyclability make them an excellent choice for the automotive industry, meeting both functional and environmental requirements.

Quality and After-sale Assurance

We promises that the name, model, specification and quantity of the equipment comply with the technical agreement. Guarantee that the equipment is excellent in craftsmanship, free from defects in design, materials, and workmanship, and meet customer needs.

we will provide service on installation and commissioning , no worry about after sales.

All equipment is delivered after passing the quality inspection and debugging.

Trade Term

Price Terms: EXW, FOB, CIF

Payment Terms: 30% as deposit, and 70% before delivery

Lead Time: 20-90 days depends on machine size and quantities

Message

PRODUCT

Related Suggestion

Blue Plastic Thermoformed Tray for Automotive Gearbox Cover

Blue Plastic Thermoformed Tray for Automotive Gearbox Cover HDPE Crankshaft Vacuum Formed Plastic Blue Tray

HDPE Crankshaft Vacuum Formed Plastic Blue Tray Grey Custom HDPE Thermoformed Transmission Cover Tray

Grey Custom HDPE Thermoformed Transmission Cover Tray Customized Thermoformed Tray for Cylinder Liner

Customized Thermoformed Tray for Cylinder Liner Customized HDPE Thermoformed Plastic Tool Tub with Leather Texture

Customized HDPE Thermoformed Plastic Tool Tub with Leather Texture Anti-scratch ABS+TPU Composite Plastic Vacuum Forming Auto Parts Packaging Tray

Anti-scratch ABS+TPU Composite Plastic Vacuum Forming Auto Parts Packaging Tray

First class quality service and professional after-sales team.

Get in Touch

*We respect your confidentiality and all information are protected.