Custom: ODM&ODM

Process Type: Thermoforming

Industrial Use: transport tray

Application: Logistics, automotive parts, 16" wheel hub

Details

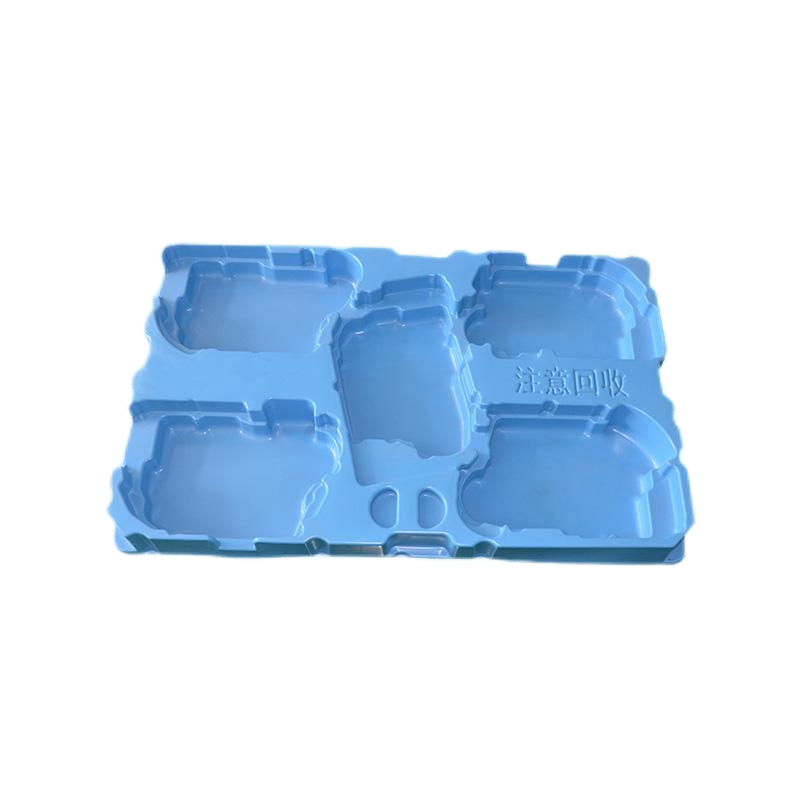

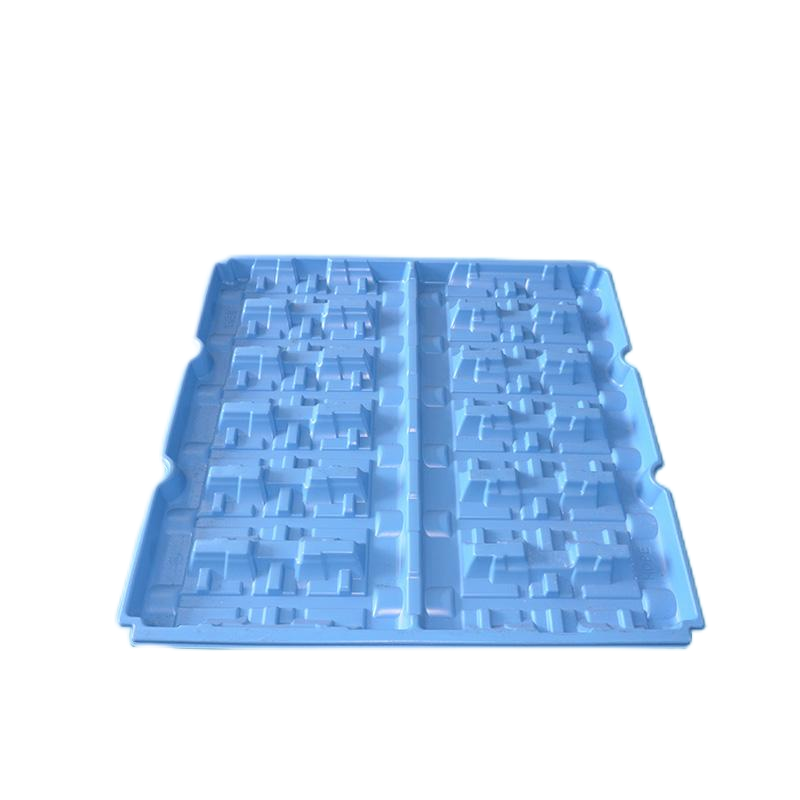

Introducing our Custom Vacuum Forming Trays for Car Flywheels:

This custom vacuum forming trays are designed specifically for car flywheels, providing secure storage, transportation, and assembly. Made from durable and rigid plastic, these trays ensure safe handling and prevent any damage to the flywheel.

Key Features:

- Protection: The tray acts as a protective barrier, preventing scratches, dents, or other damage during handling or transportation.

- Organization: Keep your flywheel organized and secure, reducing the risk of misplacement or loss.

- Efficiency: Easier handling and assembly, saving time and effort in production or maintenance processes.

- Customization: Tailored to meet specific requirements, with options for branding, labeling, and additional compartments.

The tray's design and dimensions are customized to precisely fit the contours and dimensions of your car flywheel. It may include cutouts or recesses to accommodate other components or accessories related to the flywheel.

Our vacuum forming process involves heating a pliable plastic sheet, which is then formed over a mold using vacuum pressure. The result is a custom tray that retains the shape of the mold, providing a perfect fit for your flywheel.

In addition to car flywheel trays, we offer thick gauge thermoforming products in various sizes (1 to 20mm thickness, 2000*1500*700mm dimensions), suitable for auto parts transport, casting transport, hardware accessories transport, and logistics transport. These products are space-saving, pollution-free, durable, and recyclable. Material options include HDPE, ABS, HIPS, PET, PC, PP, and other composite materials.

For other industries, we provide thin gauge blisters (0.2 to 2mm thickness) used in food, medicine, daily necessities, cosmetics, electronics, toys, stationery, agricultural production, and more. Thin gauge blisters are affordable, user-friendly, recyclable, and environmentally friendly. They are made from PVC, PET, HIPS, PP, PETG, ABS, PE, EVA, gold-plated, and flocking materials in various colors.

Choose the right material based on your specific needs and enjoy the benefits they offer. Our company prioritizes low mold cost, short production periods, and fast mold development times to reduce product costs and development cycles. We can produce products of various specifications and sizes to ensure precise assembly according to customer requirements.

Trust us to provide high-quality solutions tailored to your industry needs.

Quality and After-sale Assurance

We promises that the name, model, specification and quantity of the equipment comply with the technical agreement. Guarantee that the equipment is excellent in craftsmanship, free from defects in design, materials, and workmanship, and meet customer needs.

we will provide service on installation and commissioning , no worry about after sales.

All equipment is delivered after passing the quality inspection and debugging.

Trade Term

Price Terms: EXW, FOB, CIF

Payment Terms: 30% as deposit, and 70% before delivery

Lead Time: 20-90 days depends on machine size and quantities

Message

PRODUCT

Related Suggestion

Blue Plastic Thermoformed Tray for Automotive Gearbox Cover

Blue Plastic Thermoformed Tray for Automotive Gearbox Cover HDPE Crankshaft Vacuum Formed Plastic Blue Tray

HDPE Crankshaft Vacuum Formed Plastic Blue Tray Grey Custom HDPE Thermoformed Transmission Cover Tray

Grey Custom HDPE Thermoformed Transmission Cover Tray Customized Thermoformed Tray for Cylinder Liner

Customized Thermoformed Tray for Cylinder Liner Customized HDPE Thermoformed Plastic Tool Tub with Leather Texture

Customized HDPE Thermoformed Plastic Tool Tub with Leather Texture Anti-scratch ABS+TPU Composite Plastic Vacuum Forming Auto Parts Packaging Tray

Anti-scratch ABS+TPU Composite Plastic Vacuum Forming Auto Parts Packaging Tray

First class quality service and professional after-sales team.

Get in Touch

*We respect your confidentiality and all information are protected.